INTRODUCTION:

My

project was to use a PIC18F27K40-I/SP

8-bit PIC microcontroller to receive an infrared (IR) signal from an

IR remote (as well as one of my smartphones with an IR transmitter on

it) using the NEC protocol, display that character or command sent to

the receiver on an Liquid Crystal Display (LCD), and use pulse width

modulation (PWM) to beep a speaker every time a command is received.

The

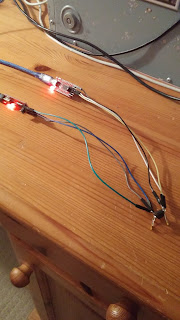

IR receiver is a TSOP4838. The microcontroller is an advanced 8-bit

device (18F PIC series). There is more memory and a few more ports

on this microcontroller but it was not needed for this project. I

wanted to be safe hardware-wise though. NEC Electronics was the

company that came up with the protocol used, and that company is now

called Renesas.

REQUIREMENTS:

The

requirements for a single-person group was to use at 3 peripherals.

The peripherals I used were digital I/O (IR encoding protocol for

data), an LCD, and PWM. No more peripherals were added since I did

not have the time to, but there is plenty of space for adding more.

I was able to satisfy my project proposal and get the commands

displayed on an LCD screen and beep every time a command was

received.

HARDWARE

DESIGN DETAILS:

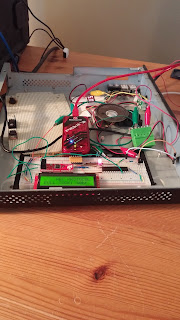

Refer

to the “Parts Used” section for what hardware was used. A

schematic and layout of the hardware used is pictured below in Figure

1. An assortment of standard parts was used, a speaker, an IR

receiver, a couple of resistors, an LED, a power supply, and LCD. A

slightly non-standard part was a serial-to-LCD converter module.

This allowed me to use only one pin for the LCD instead of 11, saving

space to expand for other peripherals or features.

Figure

1: Project Schematic / Layout

SOFTWARE

DESIGN DETAILS:

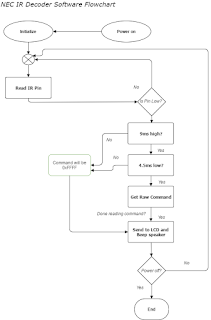

The

software was intentionally simplistic, using a polling method for the

IR receiver in a while loop and no interrupts. I do all the

initializing of the peripherals at power up:

- Making one pin a digital input for the IR receiver

- Making one pin a digital output for an LED

- Setting up a timer and an output pin for PWM

- Setting up a EUSART port with a TX pin for the LCD.

Once

everything is initialized, I have a while-loop that reads the IR pin.

If the pin is high, I just wait until it goes low. I do this to

make sure that I do not miss an incoming command, the timing is

important. When the pin goes low I begin looking for a high pulse

for 9 milliseconds. I do this with a counter variable and a delay

function that is in one of the compiler libraries for the PIC. The

function is “__delay_us()”, and it delays for the amount of

microseconds put in the parentheses. After the 9 milliseconds high,

I look for 4.5 milliseconds low. Then after waiting for that amount

of time, I can start looking for the actual payloads in the message.

First is an 8-bit address, then that address is inverted. After that

the command is sent, then that command is inverted. I did not do any

error checking but in a commercial product you would check each

address and command to be sure they are total opposites of each

other, before accepting the command. If the timing was for a logical

1 or 0, then that particular bit is set in an unsigned 32 bit

variable. After getting the command, having a small delay for the

beep of the speaker prevents “loop-back” or getting another

command immediately after. It is a kind of “debounce”, like you

would do for buttons.

Figure 2: Software

Flowchart Diagram

IMPLEMENTATION

DETAILS:

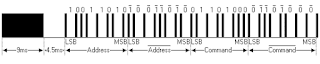

The

NEC protocol is a very popular IR protocol. It originally had an

8-bit command length, but those commands were quickly used up by

vendors. An expanded 16-bit version was created, allowing for around

65,535 commands to be used. My decoder currently is only 8-bit

however. The protocol starts with a 9 millisecond pulse high, then a

4.5 millisecond pulse low, then it begins with an 8 bit address, the

inversion of that address, then an 8 bit command, and the inverted

command.

Figure

3: NEC IR Protocol

EXPERIMENT

RESULTS AND DISCUSSION:

I

was having a little trouble getting the address for some reason, but

for my remote I know it is 0xFF. Getting the command is the most

important part and I know I was getting the correct command. An

excellent IR library [7] for the Arduino platform was used to verify

that my codes are correct. In the reference section below I will

attach all the commands from the IR remote. I visually verified with

the Arduino IR library that it was working with the IR transmitter on

my phone, which has an application that can transmit just about all

the IR protocols for TV remotes. The Vizio remote I use on my

Android phone for a Vizio TV happened to be NEC protocol and works

with the decoder.

REFERENCES:

[1] https://www.sparkfun.com/products/258

[2] https://www.sparkfun.com/products/255

[3] http://uk.farnell.com/vishay/tsop4838/ir-receiver-38khz/dp/4913190

[4] http://www.microchip.com/wwwproducts/en/PIC18F27K40

[5] http://www.sbprojects.com/knowledge/ir/nec.php

[6] http://techdocs.altium.com/display/FPGA/NEC+Infrared+Transmission+Protocol#

[7] https://github.com/z3t0/Arduino-IRremote

APPENDIX:

- The codes for one of the IR transmitters are listed below. They include the address (8 bits, not the inverted portion) and the command with the inverted command.

Gray

remote control button commands, starting with top left (red power

button) and going right, then next row, etc.

FFB24D

Decoded

NEC: FFB24D (32 bits)

FF2AD5

Decoded

NEC: FF2AD5 (32 bits)

FF6897

Decoded

NEC: FF6897 (32 bits)

FF32CD

Decoded

NEC: FF32CD (32 bits)

FFA05F

Decoded

NEC: FFA05F (32 bits)

FF30CF

Decoded

NEC: FF30CF (32 bits)

FF50AF

Decoded

NEC: FF50AF (32 bits)

FF02FD

Decoded

NEC: FF02FD (32 bits)

FF7887

Decoded

NEC: FF7887 (32 bits)

FF48B7

Decoded

NEC: FF48B7 (32 bits)

FF40BF

Decoded

NEC: FF40BF (32 bits)

FF38C7

Decoded

NEC: FF38C7 (32 bits)

FF906F

Decoded

NEC: FF906F (32 bits)

FFB847

Decoded

NEC: FFB847 (32 bits)

FFF807

Decoded

NEC: FFF807 (32 bits)

FFB04F

Decoded

NEC: FFB04F (32 bits)

FF9867

Decoded

NEC: FF9867 (32 bits)

FFD827

Decoded

NEC: FFD827 (32 bits)

FF8877

Decoded

NEC: FF8877 (32 bits)

FFA857

Decoded

NEC: FFA857 (32 bits)

FFE817

Decoded

NEC: FFE817 (32 bits)

- Only the main.c file is included here as it is where the main application code is, for the rest of the code, refer to the zip file included with the project submission.

/*

* File: main.c

* Author: Int-Mosfet

*

* Created on April 8, 2017, 11:41 AM

*/

#include <stdio.h>

#include <stdlib.h>

#include "pin_manager.h"

#define SET_BIT(var, pos) (var |= (1

<< pos))

#define CLEAR_BIT(var, pos) (var &=

(~(1 << pos)))

void main(void)

{

// Initialize the device

SYSTEM_Initialize();

//turn on LED

IO_RB6_SetHigh();

//turn off PWM

//1 is off, 0 is on (PWM)

TRISCbits.TRISC6 = 1;

// Value loaded effects volume

output

//PWM3_LoadDutyValue(0xF0);

//TRISCbits.TRISC6 = 0;

//__delay_ms(500);

//TRISCbits.TRISC6 = 1;

//RC6_SetLow();

uint8_t count = 0;

uint8_t i = 0;

//control char of 254 (0xFE)

//must be sent before a command)

uint8_t cntr = 254;

uint8_t clear_cmd = 1;

volatile uint32_t ir_code;

uint16_t address;

uint8_t command, inv_command;

//Clear screen

//EUSART1_Write(cntr);

//EUSART1_Write(clear_cmd);

//set cursor to beginning

//EUSART1_Write(cntr);

//EUSART1_Write(128);

__delay_ms(2000);

printf("ECE471 IR Decode");

printf("NEC Proto, Begin");

while (true)

{

//delay until RC7 goes low

while(IO_RC7_GetValue() ==

1);

//9ms high

while((IO_RC7_GetValue() ==

0) && (count < 200))

{

count++;

__delay_us(50);

}

//if(count > 200 || count

< 160)

// printf("FALSE

ACTIVATION");

//reset counter

count = 0;

//4.5ms low

while((IO_RC7_GetValue()) &&

(count < 100))

{

count++;

__delay_us(50);

}

//if(count > 100 || count

< 80)

// printf("FALSE

ACTIVATION");

// Read IR code, 32 bits

for(i = 0; i < 32; i++)

{

count = 0;

while((IO_RC7_GetValue()

== 0) && (count < 14))

{

count++;

__delay_us(50);

}

count = 0;

while((IO_RC7_GetValue())

&& (count < 40))

{

count++;

__delay_us(50);

}

if( count > 20)

SET_BIT(ir_code, (31

- i));

else // If space width <

1ms

CLEAR_BIT(ir_code,

(31 - i));

}

address = ir_code <<

16;

command = ir_code >> 4;

//clear screen

EUSART1_Write(cntr);

EUSART1_Write(clear_cmd);

printf(" NEC

PROTOCOL");

//printf(" CMD: ");

//printf("%x",

command);

//printf(" ");

EUSART1_Write(cntr);

EUSART1_Write(192);

printf("FULL CODE: ");

printf("%x",

ir_code);

printf(" ");

TRISCbits.TRISC6 = 0;

__delay_ms(200);

TRISCbits.TRISC6 = 1;

}

}

- List of Figures:

- Figure 2: Software Flowchart Diagram

- Figure 3: NEC IR Protocol

- Parts Used:

- PIC18F27K40-I/SP 8-bit PIC microcontroller

- 16 X 2 LCD screen (LCD-00255)

- Serial Enabled LCD Backpack (LCD-00258)

- Vishay TSOP4838 Infrared receiver, 38kHz

- 8 Ω speaker

- 220 Ω current-limiting resistor for speaker

- 1 K Ω current-limiting resistor for LED

- Breadboard

- 3-30V Volt-meter (extra add-on)

- Jumper wire

- Alligator clips

- 5V power supply